BACKGROUND

Working since 2020 with the largest European manufacturer of locks and automatic door opening and closing systems, such as shopping malls, QTS has been contacted by its client, located in Germany, to support the development of a new project of great complexity.

The challenge launched to QTS was to develop initial samples of a specific part with the aim of launching the new product on the market in 2023.

THE CLIENT PROBLEM

In addition to the fact that it is a part with high complexity, due to having several different holes and geometries, the client wanted to find a supplier that offered:

SPECIFICITIES AND REQUIREMENTS OF THE PART

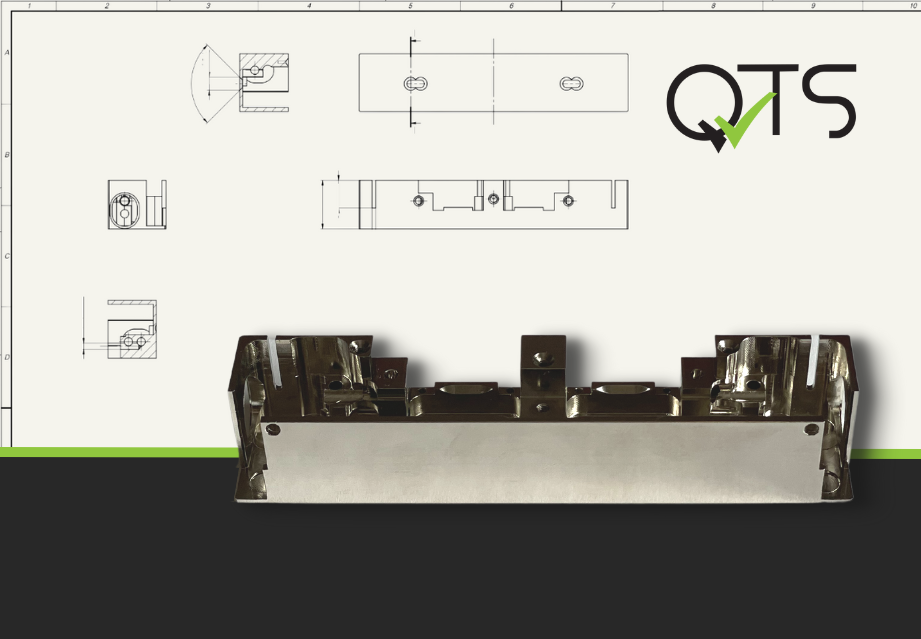

The part under analysis in this case study is one of the components that integrate a lock produced in 11 SMn30 steel, through the milling process, in a 5-axis CNC machining centre.

This is a more complete machining centre than the 3 or 4-axis, managing to perform several operations in parts that present a great complexity.

It is a very difficult part, since it has very tight tolerances, which implies varied operations throughout its production.

In this context, the part was then developed in this 5-axis CNC machining centre, with high performance tools. It should be noted that it is a machine powered by a robot process, from which the part comes out with its shape and desired geometries.

THE SOLUTION PRESENTED

From the technical design presented by the client, QTS was responsible not only for finding the ideal partner, but also to monitor the manufacture of the samples needed to start this new project of its client in Germany.

Thanks to its vast portfolio of partners, QTS quickly found the partner who owns the appropriate equipment for the manufacture of the part, having been able, in 4 weeks, to give an effective response to its client, meeting their initial expectations.

ADDED VALUE IN HIRING QTS

QTS is the right partner to monitor the projects from the beginning to the final delivery, always ensuring the specifications required by the client, and complying with the quality of the parts, always through commercial and technical support.

In this project, QTS responded to the client's problem within 4 weeks with which it committed itself, managing to find a partner that presented not only a competitive price, but also rigor in the execution of this demanding piece, and quick response.

CONCLUSION

QTS is thus contributing to the development of a new and root project, for which 10 samples of the piece presented here were produced.

These samples are now in the client's development department, and QTS is expected to be responsible for the manufacture of 2500 parts in a first batch, but which could reach 15 000 pieces in the following batches.