Marking metal and plastic parts is an increasingly essential process in a wide range of industries, particularly when it comes to identifying and tracking products from production through distribution to final delivery to the client.

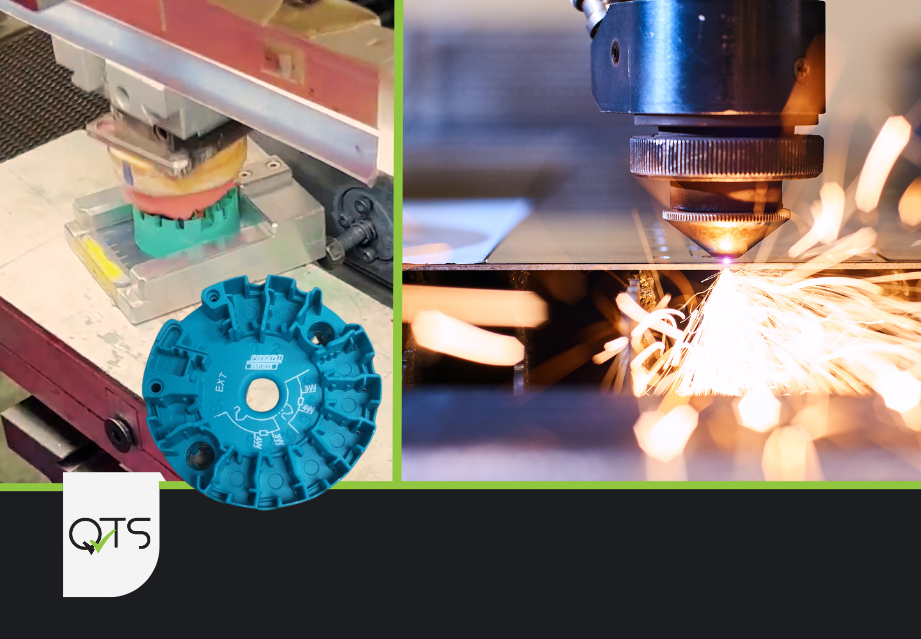

Aware of this importance, and in keeping with its purpose of finding the best solution for its customers' business and providing an integrated service from the search to the final product, QTS has added to its range of services the offer of marking methods for parts (metal or plastic): Tampography (also known as pad printing) and Laser Marking.

And here too, the service provided by QTS allows each client to concentrate all their efforts on a single partner, guaranteeing the safety of the entire process, the best quality-price and the time savings achieved by the rapid response.

In this context, it is important to note that tampography and laser marking are the most common material surface finishing techniques on the market, each with its own specific characteristics. That's why, when faced with a particular project to manufacture a part (whether metal or plastic), it's not a question of working out which technique is the best, but rather which is the most suitable for the project in question.

If, on the one hand, pad printing (tampography) is, for example, a marking method with high adaptability to materials, a variety of colours, production speed, a variety of printing effects, and so on; on the other hand, laser marking technology has, among other things, obvious advantages in terms of precision, durability, scope of application and flexibility.

Therefore, before deciding which method of marking metal or plastic parts to adopt, it is essential to first consider what result you want to achieve by analysing the differences between these two techniques. And QTS will be by your side to help!

To find out more about the pad printing and laser marking solutions offered by QTS, click here to contact us.

Make your business more competitive.ADDING VALUE TO YOUR BUSINESS is our purpose!